How Does a Leading PVC Film Manufacturer Linyang Achieve ISO9001 and ISO14001 Excellence?

Zhongshan, Guangdong Sheng Dec 30, 2025 (Issuewire.com) - What separates a Leading PVC Film Manufacturer from countless competitors in the global functional polymer materials market? For Zhongshan Linyang Plastic Co., Ltd., the answer lies in methodical implementation of ISO9001 Quality Management Systems and ISO14001 Environmental Management Systemstwin certifications that transform operational philosophy from reactive problem-solving to proactive excellence. This achievement reflects 25 years of systematic improvement, technical investment, and unwavering focus on delivering consistent quality while minimizing environmental impact.

The Foundation: Understanding ISO Excellence Requirements

ISO9001:2015 and ISO14001:2015 represent more than certificates displayed in corporate lobbies. These internationally recognized standards establish frameworks for organizations to design, implement, and continuously improve management systems addressing quality assurance and environmental responsibility. ISO9001 defines how to establish, implement, maintain, and continually improve a quality management system, while ISO14001 provides a framework for organizations to design and implement an environmental management system and continually improve their environmental performance.

For manufacturers like Linyang, achieving these certifications requires fundamental shifts in operational thinking. Quality can no longer be inspected into products at the end of production linesit must be built into every process from raw material procurement through final delivery. Environmental considerations cannot be afterthoughts addressed only when regulations mandatethey must integrate into strategic planning, resource allocation, and daily operations.

The implementation journey begins with gap analysis, where existing operations are measured against standard requirements to identify where changes are needed. This diagnostic phase reveals process weaknesses, documentation deficiencies, and areas requiring additional controls. For Linyang, this assessment highlighted opportunities to formalize quality protocols across six calendering production lines while implementing systematic environmental monitoring throughout the 33,333 square meter facility.

Systematic Implementation: Building Quality into Every Process

The key is to define all the processes in your company and look at how they interact within your organization, as it is in these interactions that problems can occur. Linyang's approach to ISO9001 implementation focused on mapping process flows from raw material receiving through finished product shipping, identifying critical control points where quality could be assured or compromised.

The company's calendering operations presented specific challenges for quality consistency. This production method passes materials through precision-controlled heated rollers to achieve uniform thickness and optimal physical properties. Temperature variations, pressure inconsistencies, or material flow irregularities can create defects affecting entire production runs. Linyang addressed these risks by installing computer monitoring systems tracking multiple parameters continuously, with automated alerts triggering corrective action before specifications drift outside acceptable ranges.

More On Toptelecast ::

- Lori Ann Mertens, Recognized by BestAgents.us as a 2025 Top Agent

- Al-Rabiya Auto Accessories and Onyx Coating Celebrate 10 Years of Car Care Excellence in the Middle East

- Openex: The Future of China Steel Fabrication is Here

- Vayaki Tour Launches in Delhi, Offering Curated Luxury Journeys to Andaman, Japan, and the Philippines

- It’s Blue Skies Over Perth City for Skydive Geronimo During Rottnest Maintenance

Raw material quality directly influences finished product performance. As a Best Pve Film Conpany Fron China, Linyang implemented supplier qualification protocols ensuring incoming PVC compounds, plasticizers, and polyester base fabrics meet defined specifications. Incoming inspection verifies materials before they enter production, preventing defective inputs from compromising finished goods. This upstream quality control reduces waste, minimizes rework, and protects customer satisfactioncore objectives of effective quality management systems.

Documentation forms the backbone of ISO9001 compliance. Linyang developed procedures defining how each critical process should be executed, specifying responsibilities, required equipment, measurement methods, and acceptance criteria. These documented procedures ensure operations proceed consistently regardless of which shift operates the equipment or which operator performs the task. Not all processes need to be documented procedures, but it is important to decide which ones need to be in order to ensure compliant products and services.

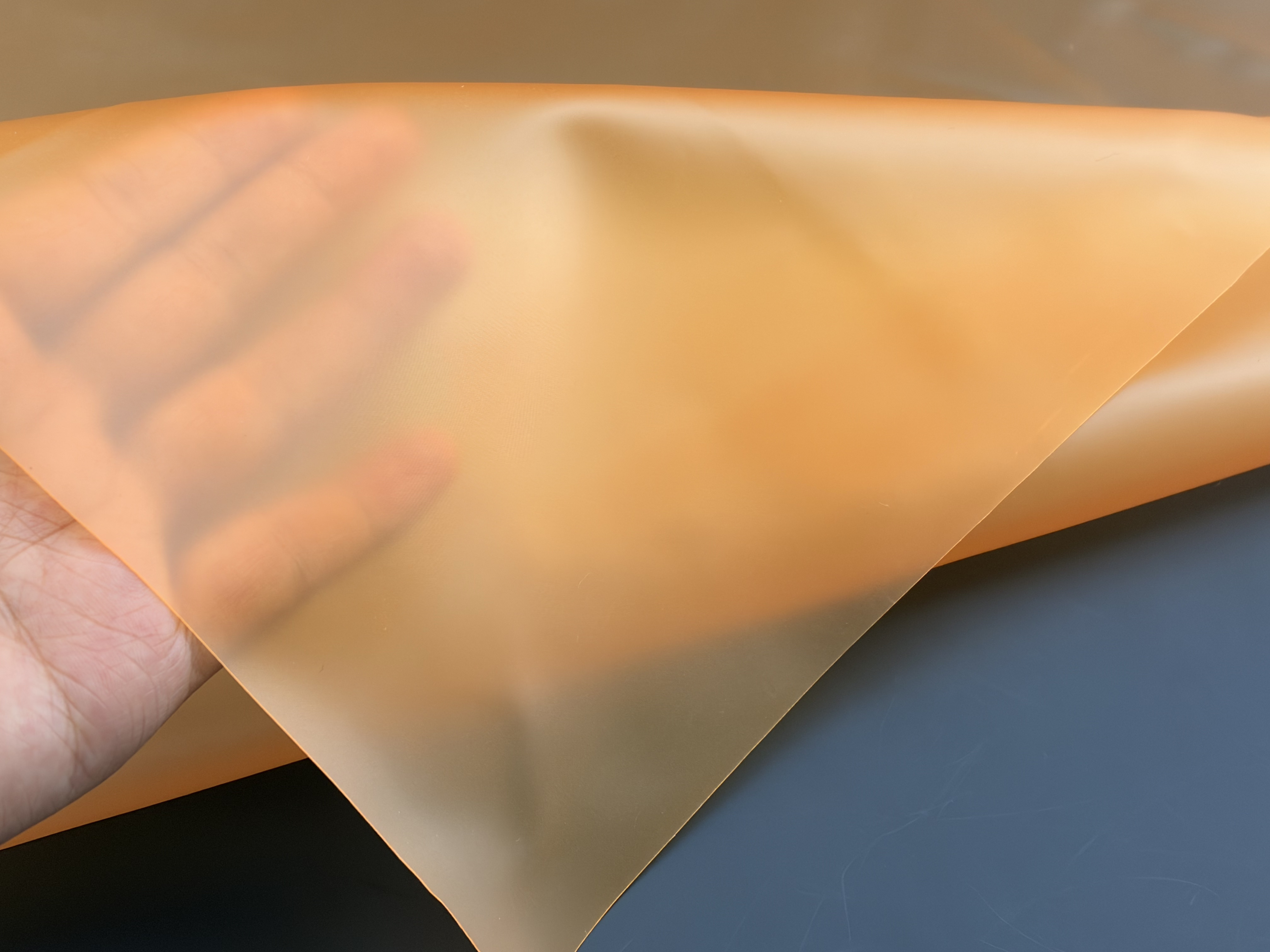

Product Excellence: PVC Film Quality Through Systematic Control

Linyang's PVC film product range demonstrates how quality systems translate into superior products. The company's transparent film series includes super clear film, normal transparent film, and specialized variants such as anti-fog and UV-resistant formulations. Each product type requires specific technical parametersclarity measured by haze percentage, tensile strength verified through standardized testing, dimensional stability confirmed across temperature ranges.

The super clear film product line exemplifies precision manufacturing. Achieving optical clarity comparable to glass requires exceptional purity in raw materials, precise temperature control during calendering, and contamination-free production environments. Linyang's quality management system addresses each factor through documented procedures, environmental controls, and verification testing. The result is film consistently meeting stringent clarity specifications demanded by packaging, stationery, and decorative applications.

Embossed film production adds complexity through pattern application during calendering. Pattern depth must remain consistent across the entire film width and throughout production runs, as variations create visual inconsistencies unacceptable in tablecloth, upholstery, and decorative applications. Linyang's process controls monitor roller temperature, pressure distribution, and material feed rates to maintain pattern uniformityquality attributes verified through regular sampling and measurement.

Environmental-friendly film formulations reflect both ISO14001 principles and market demand for sustainable materials. These products incorporate modified plasticizer systems, recycled content where specifications permit, and additives reducing environmental impact during use and disposal. Developing these formulations required technical research, testing to verify performance equivalence, and documentation demonstrating environmental advantagesefforts aligning with environmental management system requirements.

Environmental Excellence: Minimizing Impact Through Systematic Management

ISO14001 implementation required Linyang to identify environmental aspects of operationselements of activities, products, or services that interact with the environment. For PVC film manufacturing, significant aspects include energy consumption by calendering equipment, waste generation from production scrap, emissions from heated processing, and water usage in cooling systems.

Organizations need to define processes and procedures necessary to ensure consistent and adequate results when preventing negative environmental impacts and to respond to emergency situations. Linyang developed procedures addressing each identified environmental aspect, establishing controls preventing pollution, reducing resource consumption, and ensuring compliance with environmental regulations.

Energy efficiency improvements focused on calendering equipment, which consumes substantial electricity heating rollers to processing temperatures. Linyang invested in energy-efficient heating systems, insulation reducing heat loss, and process optimization minimizing equipment warm-up periods. These technical improvements reduced energy consumption per unit of production while maintaining quality standardsdemonstrating how environmental and operational objectives aign when systematically addressed.

Waste reduction strategies target production scrap generated during material changeovers, specification adjustments, and quality rejections. Linyang implemented procedures for segregating clean scrap suitable for recycling, distinguishing it from contaminated material requiring alternative disposal. By returning clean scrap to production streams where specifications permit, the company reduces raw material consumption and landfill wastedual benefits reflecting environmental management principles.

China TOP Pvc Fabric Manufacturer: Technical Capabilities Supporting Certification

Recognition as a China TOP Pvc Fabric Manufacturer requires manufacturing infrastructure supporting both quality consistency and environmental responsibility. Linyang's six calendering production lines operate with specialized capabilities addressing different product specificationssome configured for ultra-thin films requiring precise thickness control, others optimized for heavy-duty tarpaulin production.

The specialized calendering and laminating unit producing 6.5-meter-wide tarpaulins demonstrates advanced technical capability. Wide-format production presents quality challenges as maintaining uniform properties across the entire width becomes increasingly difficult as dimensions expand. Linyang's success with wide-format materials reflects sophisticated process control, equipment precision, and operator expertise developed through years of systematic improvement.

Monthly production capacity exceeding 3,000 tons enables Linyang to fulfill substantial contracts while maintaining quality consistencya capability essential for major projects and institutional buyers. This production scale requires systematized operations where quality cannot depend on individual expertise but must be built into processes, procedures, and verification systems. ISO9001 frameworks provide the structure ensuring consistent output regardless of production volume.

The company's workforce of over 150 employees undergoes regular training ensuring understanding of quality requirements, environmental responsibilities, and their role in maintaining management systems. Employees should have training on what ISO 9001 is, so that they are aware of why you are doing this, as well as the important training of any changes to the processes they are involved in. This training culture ensures certifications reflect operational reality rather than documentation disconnected from actual practices.

Continuous Improvement: The PDCA Cycle in Practice

ISO 9001's operating principle is the Plan-Do-Check-Act (PDCA) cycle which is a quality management methodology that aims to continuously improve processes. Linyang applies this cycle throughout operations, planning improvements based on performance data, implementing changes systematically, checking results against objectives, and taking action to standardize successful improvements or revise unsuccessful approaches.

Internal audits form critical components of continuous improvement systems. Trained auditors periodically evaluate processes, procedures, and documentation to identify nonconformities, potential improvements, and best practices deserving broader application. These audits provide objective assessment of management system effectiveness while identifying opportunities for refinement before external certification audits occur.

Management reviews bring senior leadership together periodically to evaluate quality and environmental performance data, assess customer feedback, review audit findings, and direct improvement initiatives. These reviews ensure management systems receive adequate resources, that objectives align with strategic direction, and that certification maintenance remains organizational priority rather than quality department responsibility alone.

China Leading Pvc Film Manufacturer: Market Recognition Through Certified Excellence

Export presence spanning more than 60 countries validates Linyang's quality management effectiveness. International markets impose stringent requirements for material performance, safety compliance, and environmental responsibility. Success across diverse regulatory frameworks requires capability to meet varied standards while maintaining competitive pricinga balance achieved through manufacturing efficiency enabled by systematic quality management.

Customer applications span packaging, stationery, inflatable products, tablecloths, decoration, printing, laminating, and handbagsindustries where material consistency proves critical for processing efficiency and product quality. Linyang's certified quality systems provide customers confidence that specifications will be met consistently, delivery schedules maintained reliably, and technical support available when application challenges arise.

The company's 25-year operational history demonstrates sustained commitment to quality evolution. Annual output value exceeding 60 million US dollars reflects both production scale and market acceptance of Linyang's quality proposition. This financial performance validates that quality investment generates returns through customer retention, premium positioning, and operational efficiency reducing waste and rework costs.

For businesses exploring PVC film and fabric suppliers, ISO9001 and ISO14001 certifications provide objective evidence of management system maturity. These certifications signal systematic approaches to quality assurance and environmental responsibility rather than ad hoc responses to immediate problems. Detailed information about Linyang's certified capabilities and comprehensive product range is available at https://www.linyangplastics.com/

Source :Linyang

This article was originally published by IssueWire. Read the original article here.