The Next Generation of Heavy Fabrication: Key Takeaways from the AWS Welding Summit 2025

Xiamen, Fujian Nov 15, 2025 (Issuewire.com) - Global heavy fabrication is about to undergo a significant transformation. The traditional methods of fabrication are being replaced by a new age that is characterized by the use of advanced technology, sustainability, and unprecedented precision. Understanding these shifts, for any Custom Heavy Fabrication Company that wants to stay on top of the game, is more than just an advantage. It's a requirement. The AWS Welding Summit, an event which brought together some of the best minds in the metal fabrication industry, was based on this forward-looking approach. The summit, which took place from August 6th through 8th in the scenic Woodlands Resort of Texas, offered a comprehensive view of the trends and innovations to define the next decade.

The New Horizon of Welding Technology

The AWS Welding Summit 2025 was centered around innovation as the driver of progress. Experts stressed that the future of weld is not just about joining metal pieces together; it's also about integrating robotics and advanced materials in order to achieve higher levels of quality and efficiency.

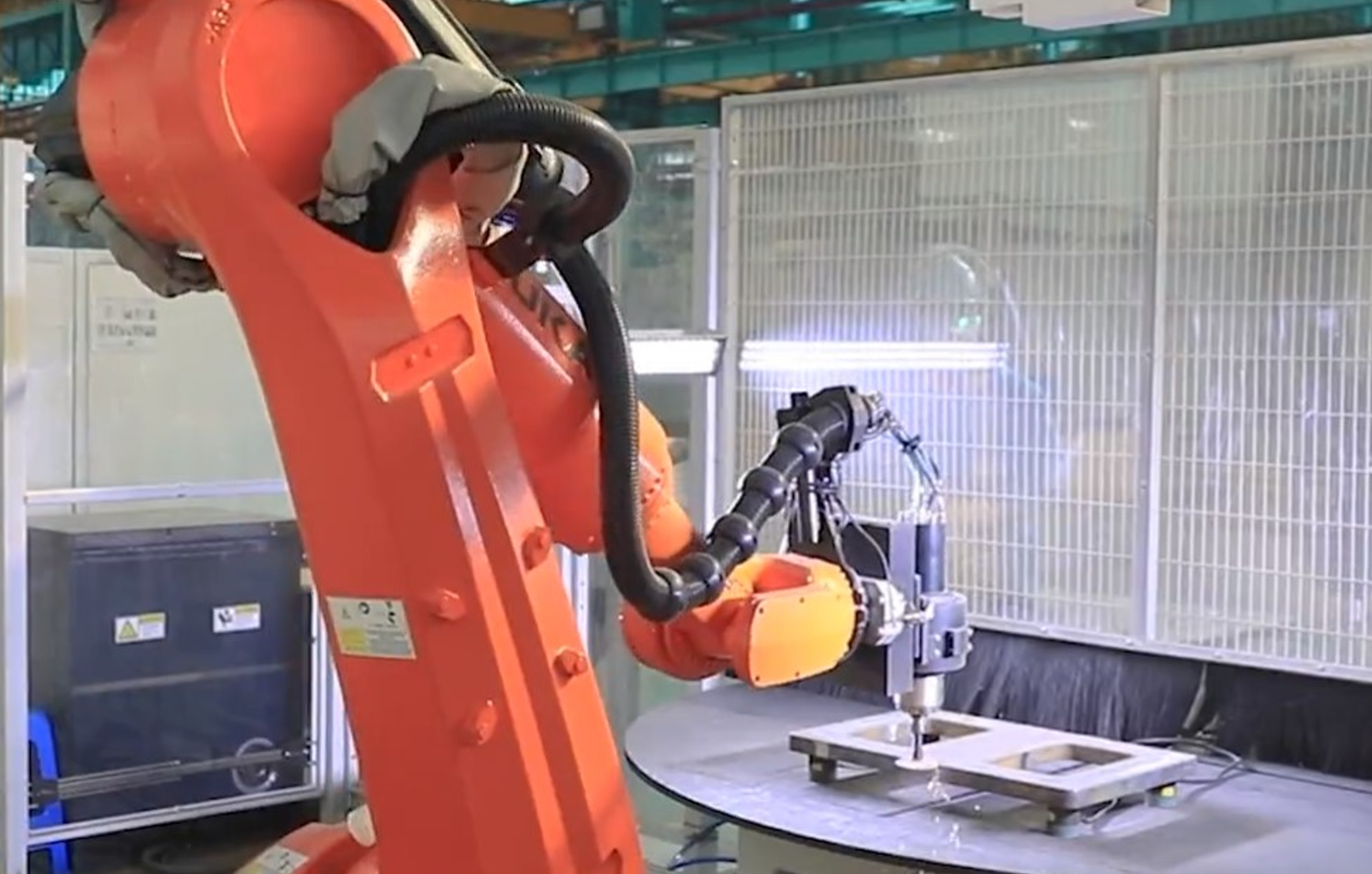

Automation and Robotics - Precision at Scale

The rapid adoption of robotics and automation was a key theme of the summit. The presenters emphasized how robotic welding is becoming a necessity for large-scale projects, and not just a luxury. These systems are able to achieve unmatched accuracy and repeatability, reducing the risk of human error and improving quality control. This technology is ideal for businesses that perform repetitive, complex tasks. It not only increases productivity, but it also improves worker safety, by keeping them out of hazardous environments. The attendees learned about the latest collaborative robots that work with human welders and AI-driven system that can self correct during the welding process to ensure flawless results. The shift to intelligent automation has fundamentally changed the way major components, such as industrial machinery and structural steel, are constructed.

Safety and Sustainability in Modern Fabrication

The summit focused on more than just technology. It also placed an emphasis on the responsibility of the industry towards the environment and the workforce. The discussions focused on adopting safer manufacturing processes and creating safer workplaces without compromising performance.

Materials and Techniques to Create a Greener Tomorrow

More On Toptelecast ::

- Denver Specialty Supply Store Reports Growth Supporting Independent Concrete Coating Contractors

- Imagen Network Adopts Gemini Models to Power Adaptive Social Engagement

- Leading China Factory Pioneers Industrial PLC for Vending Stability and Automated Sterilization Compliance

- Amy L. Zimet, PhD: Guiding Minds Toward Healing in the Heart of New York City

- China's Top 3 Billiard Table Manufacturers: Benchmarking Excellence in the Global Billiards Equipment Industry

Sustainability is driving a revolution within materials science. The summit featured panels that discussed the use of lighter and stronger alloys, composites, and other materials to reduce waste and energy during production. The presentations on advanced welding techniques such as laser and friction stir welding demonstrated how they could create superior joints using minimal heat input. This led to less distortion and required less post-weld finish. The focus on material optimization and efficiency is not only environmentally friendly, but it also leads to significant cost savings for fabrication companies. Openex is one company that embraces these methods to deliver high-performance, cost-effective products.

Digital Transformation and Its Role

The summit focused on the integration of digital tools into modern manufacturing. Experts discussed how these technologies streamline the entire fabrication process.

The summit included exciting demonstrations of VR training simulators that allow aspiring welders the opportunity to improve their skills in an affordable, safe virtual environment. Discussions on digital twin technology also highlighted how companies could create a virtual copy of a component or structure even before cutting any steel. This technology allows the early detection and correction of design errors, which can prevent costly mistakes down the road. Integration of IoT devices (Internet of Things), with sensors on components and equipment, was also a major theme. These devices provide real-time data for monitoring performance, predicting maintenance needs and ensuring optimal operational efficiency.

Here below is a Digital Twin application developed by Openex which enable the mechanical engineer to observe a complex component before starting manufacturing.

Openex, a leader in the Fabrication Revolution

The AWS Welding Summit was a look into the future. However, companies such as Openex have already embraced its principles. Openex, as a leader in the manufacturing of steel welding and fabricated metal products, has been in the industry for many years. They specialize in heavy fabrication to meet the demands of customers around the world.

Unmatched Core Capabilities and Core Advantages

Openex's foundation is quality, service and a proactive attitude to technology. They offer a wide range of services, which goes beyond traditional fabrication. This makes them a reliable partner for complicated projects.

A seamless process from prototype to production

Openex is known for its ability to take a concept and turn it into a market-ready, finished product. They can turn a client's idea into a full-scale product in the required time frame and with the desired quality using their high-tech equipment and highly-experienced team. This integrated, seamless process eliminates the complexity of managing multiple vendors and ensures a consistent, efficient workflow. The company's strict quality control standards are based on delivering the best possible service and quality to customers. This ensures that each component is manufactured according to the exact specifications and performs flawlessly even under the most extreme conditions.

Tailored Solutions to Diverse Industries

Openex has a product portfolio as diverse as its clients. Each component is carefully engineered to fit a specific application. Openex's experience allows it to provide specialized solutions, not a one size fits all approach. Openex produces robust safety structures, heavy duty machine frames and specialized housings for the mining industry. These can withstand harsh environments. Openex produces high-pressure pipes, offshore platforms, and durable components for wellheads that meet the highest safety standards in the oil industry. Openex is a leading supplier of precision-machined engine mountings, complex chassis parts, and specialized tools for the automotive and aerospace industries. Openex also provides structural steel beams for energy and foundation supports for modern infrastructure. Openex's versatility and attention-to-detail demonstrate its ability to be more than just a supplier. It is rarely seen, a heavy part containing procedures of roll bendingwelding and machining like below surprised the customer by Openexs high quality and short delivery.

A Global Force: A Trusted Partner

As the global supply chain becomes more integrated, Openexs role as a leading China Heavy Fabrication Manufacturer has become increasingly significant. The companys ability to combine competitive pricing with world-class quality and rapid delivery has made them a go-to partner for businesses worldwide.

Openex is a leader in the industry for companies looking to partner with a company that can handle large-scale fabrication and machining. Openex is not only keeping up with the evolution of the industry, but they are also actively driving it forward. They have proven that technology, expertise and a commitment to their customers are the key ingredients for success.

Trust Openex for your large machining and fabrication needs.

Visit their website to learn more about their capabilities and how they can help elevate your next proect: https://www.cncmetalworking.com/

Media Contact

Openex

+86 186 5928 0806

Our Offices:No. 99 Yilan Rd., Xiamen , CN.

Source :Openex

This article was originally published by IssueWire. Read the original article here.