Why Lonovae, the China Top Sleeve Pack Containers Supplier, is Key to Unlocking the Future of Logistics

Jiangyin, Jiangsu Sheng Oct 29, 2025 (Issuewire.com) - I. Introduction: Defining Excellence in Returnable Transport

The operational landscape of global logistics is undergoing a fundamental transformation, demanding packaging solutions that are not only robust and cost-efficient but also aligned with stringent global sustainability goals. In this high-stakes environment, Returnable Transport Packaging (RTP) has emerged as the clear path forward, and companies specializing in advanced polymer engineering are leading the revolution. At the forefront of this movement is Jiangyin Lonovae Technology Co., Ltd.

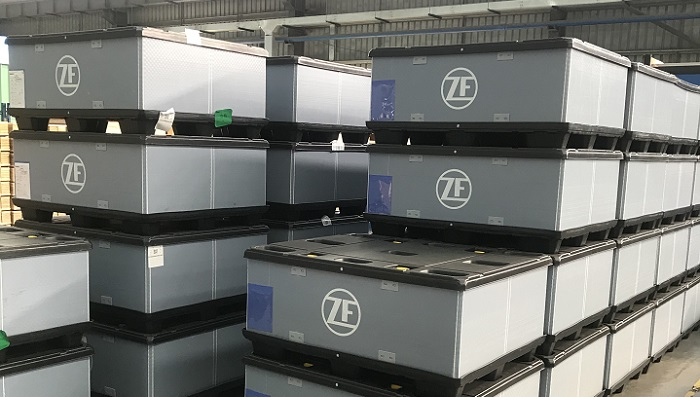

Since its founding in 2015 in Jiangyin city, China, Lonovae has dedicated its more than 100 staff and 3,000 square meter facility to pioneering RTP solutions. Central to their success and a critical component for modern supply chains is the China Top Sleeve Pack Containers Supplieran advanced, three-piece collapsible unit. These containers, consisting of a pallet, a lid, and a sleeve crafted from high-strength PP Honeycomb Panel, are prized for their exceptional durability, ability to protect sensitive goods, and, most critically, their capacity to collapse into minimal volume. This feature dramatically cuts down on return freight costs and maximizes warehouse efficiency, helping countless companies find environmentally friendly and sustainable logistics applications. Lonovaes recent expansion into personal and home care products further highlights their versatile commitment to health and cleanliness.

II. Industry Outlook: The Strategic Trajectory of Sustainable Logistics

The market for Returnable Transport Packaging is experiencing an explosive growth phase, fueled by macroeconomic drivers and technological shifts. This section provides an analysis of the trends that position Lonovae's products as essential tools for future-proofing global supply chains.

A. Global Mandates for Circularity and Net-Zero Goals

The primary driver is the global regulatory and corporate push towards a circular economy. Increasingly strict mandates regarding packaging waste in key markets necessitate a definitive shift away from single-use materials. RTP, by its inherent multi-trip design, offers a verifiable solution to reduce waste generation and lower the embedded carbon footprint of logistics operations. Companies adopting Lonovae's solutions are directly contributing to their corporate sustainability targets, turning what was once a cost center (packaging disposal) into a long-term asset (reusable container fleet). This structural demand guarantees sustained growth in the sleeve pack container segment.

B. The Rise of Smart Packaging and Automation

More On Toptelecast ::

- Europe Study Centre Brings Technical University of Košice, Slovakia to Kumaraguru College, Coimbatore

- How ACS Customizable PET Film Solutions Can Boost Your Product’s Durability And Aesthetics

- Brian Baldari on the Three Rules for Resilience Forged in the Refining Fire of Experience to Mentor the Next Generation

- Leisa Ormsbee, Recognized by BestAgents.us as a 2025 Top Agent

- Zhongshan Wiseprint as China’s Leading CE-Certified ElectroInk OEM

The modernization of industrial processes through Industry 4.0 demands packaging that is uniform, standardized, and adaptable to automation. Lonovaes precisely manufactured plastic collapsible containers meet the dimensional tolerances required by robotic handling systems. Furthermore, the integration of smart technologiessuch as IoT sensors and RFID chips for tracking, temperature monitoring, and inventory managementis becoming standard. Durable plastic components, particularly the stable PP Honeycomb Panel used in sleeve boxes, provide the ideal, long-lasting platform for these digital enhancements, ensuring that RTP remains central to the future of smart logistics.

C. Specialized Demand from High-Growth Industries

Specific high-value sectors are intensifying the demand for advanced RTP. The electric vehicle (EV) industry, for instance, requires specialized containers for transporting sensitive and often volatile battery components, where the non-corrosive nature and structural integrity of plastic sleeve boxes are critical safety and operational requirements. Similarly, the pharmaceutical and high-end manufacturing sectors rely on high-grade, easily sanitized plastic packaging to maintain product quality and integrity throughout complex, often international, supply chains. Lonovaes focus on robust, engineered plastics directly addresses these critical needs.

III. Lonovaes Core Strengths: The Five Pillars of Logistics Excellence

Lonovaes reputation as a key player in sustainable logistics is built upon a concentrated focus on innovation, quality, and comprehensive customer support. The company's core strengths can be defined by five distinct pillars that offer measurable value to its global clientele.

1. Advanced Material Engineering (PP Honeycomb Panel Mastery)

Lonovaes competitive edge is anchored in its material science expertise. The use of PP Honeycomb Panel for the sleeves of its Pallet Pack Containers is a critical differentiator. This material provides an exceptional strength-to-weight ratio, superior cushioning, and inherent resistance to moisture, corrosion, and many industrial chemicals. This ensures maximum product protection in harsh environments while keeping the unit light enough for manual handling and cost-effective return shipping.

2. Superior Collapsibility and Cost Reduction

The fundamental economic advantage of Lonovaes collapsible products lies in their design for maximum space savings. Their sleeve pack containers fold down to a fraction of their assembled height, typically achieving a 70-80% reduction in volume on the empty return trip. This feature directly translates to a massive reduction in backhaul transportation costs and dramatically frees up valuable warehouse space, delivering immediate and measurable savings to the customer.

3. Unwavering Durability and Longevity

Focused on the Returnable Transport Packaging segment, Lonovae engineers its products for extended lifecycles and high turnover rates. The robust injection-molded pallets and lids, combined with the resilient PP honeycomb sleeves, ensure resistance to impacts, temperature variations, and heavy loads. This longevity directly minimizes the Total Cost of Ownership (TCO) for clients, as replacement rates are significantly lower than those for traditional, less durable packaging.

4. Manufacturing Consistency and Standardization

As a key supplier, Lonovae ensures its products adhere to strict international dimensional standards (e.g., ISO and Euro footprints). This precision is vital for large clients who use their containers in automated warehouses or in cross-border logistics systems. The consistency of Lonovaes molding and assembly processes guarantees seamless compatibility with existing material handling equipment, from conveyors to automated guided vehicles (AGVs).

5. Versatile Product Portfolio and Dual Business Model

While sleeve pack containers are a specialization, Lonovae offers a comprehensive RTP portfolio, including Collapsible Bulk Containers and Collapsible Crates, making them a one-stop shop for diverse packaging needs. Furthermore, their strategic expansion into personal and home care products leverages their core plastic manufacturing expertise, demonstrating a versatile and adaptive business model focused on both industrial efficiency and consumer cleanliness.

IV. Application Scenarios and Client Success Stories

Lonovaes solutions are deployed across a broad spectrum of demanding industrial environments, translating their core strengths into tangible operational benefits for clients.

A. Automotive Manufacturing and Supply Chain

The automotive sector is the largest consumer of sleeve pack containers due to the need to safely transport large, irregularly shaped components (like body panels, dashboards, and engine parts) on a closed-loop basis. Lonovaes containers are utilized by Tier 1 and ier 2 suppliers for inbound logistics, where the structural protection afforded by the PP honeycomb material is crucial for preventing damage to high-value parts during transit between factories.

B. Electronics and High-Tech Industries

For the electronics industry, especially in the movement of circuit boards, delicate sensors, or partially assembled devices, the cleanliness and optional ESD (Electrostatic Discharge) properties of Lonovaes plastic products are paramount. The sleeve pack containers ensure components are protected from contamination and physical shock, maintaining the integrity required for high-precision manufacturing.

C. General Industrial and Retail Logistics

The Collapsible Bulk Containers are essential for handling raw materials (e.g., plastic pellets, metal components) and finished goods in general manufacturing. Collapsible Crates, meanwhile, are widely adopted by the retail and fresh produce sectors, where their easy sanitation, stacking capability, and visibility (for ventilated designs) optimize distribution from sorting centers to retail shelves. In these applications, Lonovaes products streamline inventory management and accelerate shelf restocking.

While specific client names remain confidential under NDA, Lonovae has facilitated significant operational improvements for Fortune 500 companies in these sectors, often resulting in projects that cut annual packaging procurement costs by over 40% and achieve nearly 100% recyclability of the packaging material at the end of its long service life. This proven track record underscores Lonovaes value as a strategic logistics partner.

V. Conclusion: Partnering for Sustainable Growth

Jiangyin Lonovae Technology Co., Ltd. is not simply a manufacturer; it is a vital enabler of modern, sustainable, and cost-efficient logistics. By specializing in advanced Returnable Transport Packagingfrom collapsible bulk containers to their signature sleeve pack solutionsLonovae provides the critical infrastructure necessary for global businesses to navigate the complex demands of the 21st-century supply chain. Their commitment to material innovation and operational efficiency makes them a key partner in unlocking the full potential of global logistics.

To explore Lonovaes full range of Returnable Transport Packaging solutions and their commitment to sustainable manufacturing, please visit their official website:

Media Contact

Jiangyin Lonovae Tenology Co., Ltd.,

8618661010305

Source :Jiangyin Lonovae Tenology Co., Ltd.,

This article was originally published by IssueWire. Read the original article here.